Automated upgrades are like playing a game and dungeons, you can't challenge the ultimate boss right away. If we jump directly from a completely manual production line to full automation, it's like driving a racing car for beginners, which not only makes it easy to overturn (cost overruns, decreased efficiency), but may also damage the car (chaotic process). Therefore, the most reasonable approach is to steadily upgrade in stages, just like climbing stairs, step by step towards intelligent manufacturing.

Stage 1: Partial Automation - "Machine Assisted, Human Led"

Core Features

The typical feature of this stage is the mechanization of some processes, but manual labor still plays an important role. Machines are responsible for standardized processing tasks, while humans are responsible for loading, debugging, handling, and some complex processes.

Automated content

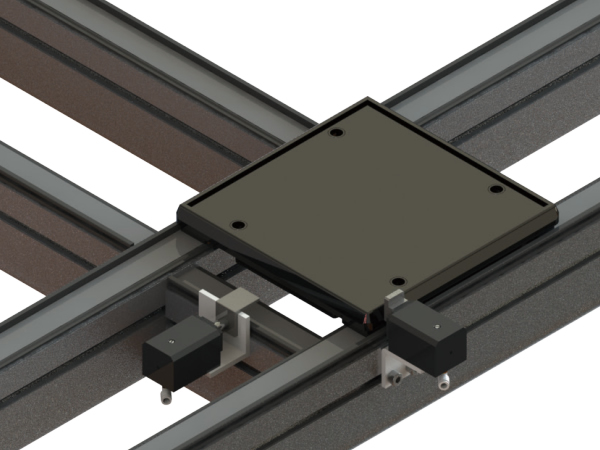

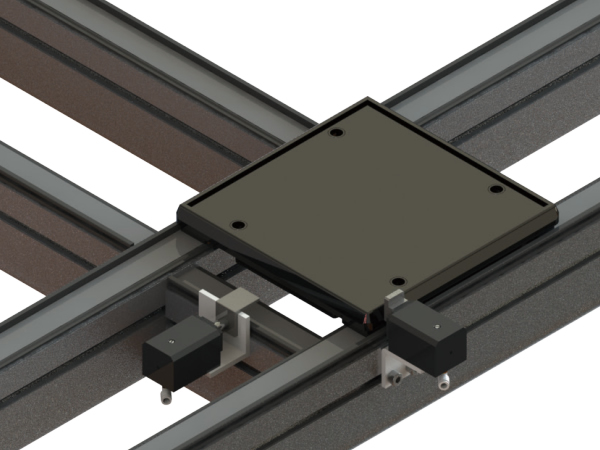

Equipment application: Automatic processing is achieved through the use of machining centers, laser cutting, turret punch presses, and other equipment; Robot spraying, automatic welding and other processes are mechanized.

Manual collaboration: Material handling and assembly are mainly completed manually; Manually responsible for flexible tasks such as material placement, component assembly, and quality inspection; Complex or refined welding, bending and other processes still rely on manual experience.

Applicable scenarios

Suitable for traditional manufacturing factories to initially attempt automation. These types of factories hope to improve efficiency by starting with certain processes while maintaining production flexibility. For example, small and medium-sized hardware factories can first introduce automation equipment in highly repetitive processing links to reduce labor intensity for workers and gradually accumulate automation experience.

Stage 2: High degree of automation - "machine led, human assisted"

Core Features

At this stage, the degree of automation has significantly increased, with robots and automated equipment undertaking the majority of production tasks, while workers are mainly responsible for equipment monitoring, anomaly handling, and final quality inspection.

Automated content

Process upgrade: Production equipment achieves full automation of processing, welding, painting and other operations; Robots complete the handling, transportation, and assembly of workpieces; The automatic detection system replaces manual quality inspection, improving detection accuracy and efficiency.

Labor function transformation: Workers shift from direct operation to monitoring equipment operation, handling incoming material inspection, equipment maintenance, production abnormalities, and other situations; Some complex assembly processes still require manual participation, and the product packaging process may also retain manual operations.

Applicable scenarios

Suitable for factories that already have a certain level of automation foundation, with the goal of further reducing manual intervention, improving production efficiency and quality stability. For example, after introducing robot production lines, medium-sized electronics factories can free up manual labor from repetitive work and focus on equipment management and quality control, achieving a significant improvement in production efficiency.

Stage 3: Comprehensive Automation - "Smart Factory, Unmanned"

Core Features

The production line achieves full process automation, with intelligent systems leading production decisions, and manual labor only responsible for equipment maintenance, system monitoring, and strategy adjustment.

Automated content

Full process intelligence: Production, assembly, testing, packaging and other processes are all completed by automated equipment; Real time monitoring of production status through the Internet of Things (IoT), supporting remote device control; The automatic inventory management system tracks parts inventory in real-time and automatically triggers the replenishment process when there is a shortage of materials; AI technology analyzes production data to optimize production efficiency and resource allocation.

Artificial role positioning: Personnel are mainly engaged in equipment maintenance, system upgrades, and handling of abnormal situations; Adjust production strategies based on data analysis results, conduct data optimization analysis, and promote continuous improvement of production processes.

Applicable scenarios

Suitable for enterprises pursuing high-precision manufacturing and large-scale standardized production, such as automotive manufacturing, 3C product production, and other industries. The intelligent factory mode can achieve 24-hour continuous production, significantly improving production efficiency, reducing labor costs, and supporting precise control of complex production processes.